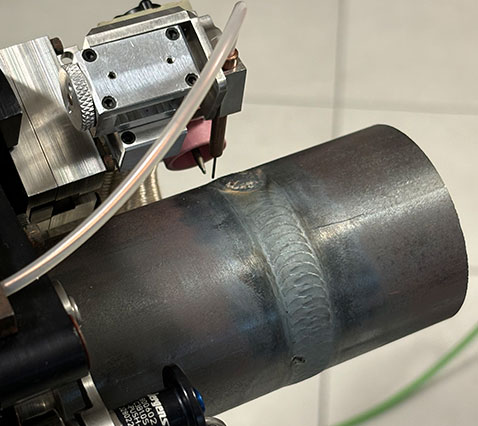

- Function: multi-pass orbital GTAW pipe-to-pipe, pipe-to-fitting

- Materials: carbon-based and exotic alloys

- Power supply compatibility: Pipemaster 515 and Pipemaster 516

The Magnatech D-Head 420 weld head is designed to make pipe-to-pipe and pipe-to-fittings welds. It reproduces all required functions, motions, and flexibility of highly skilled manual welding, reduces repair rates, while offering high repeatability and efficiency. The D-Head 420’s key differentiator is its ability to be used on applications with radial and axial clearance constraints. The minimum required clearance is 2″ / 51 mm, making it a unique weld head for particular applications across various industries. The D-Head is positioned on the pipe using interchangeable guide rings (standard 24 guide ring sizes are available). Guide ring insert kits can be used allowing to cover the diameter range of 0.84 – 14″ / 21.34 – 355.60 mm o/d.