The Magnatech Pipeliner Pro is a mechanized orbital GMAW/FCAW pipe welding system, engineered for high-performance applications. It integrates advanced Fronius technology through the TPS400i Digital Inverter Power Source, offering exceptional welding control and reliability.

System programming and parameter management are facilitated via the Magnatech Pipeliner Digital Programmer (PDP), which features a 10.4-inch color touchscreen interface and a wired remote pendant for precise, real-time adjustment during welding operations.

The complete Pipeliner Pro welding machine consists of:

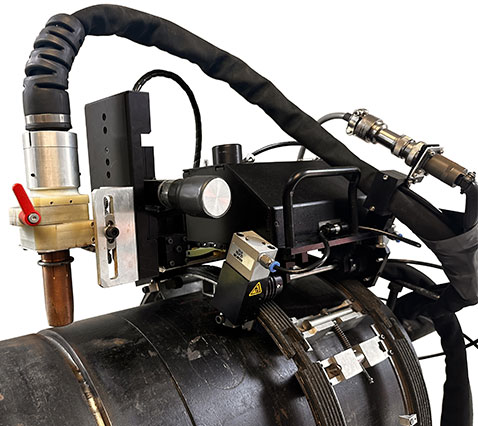

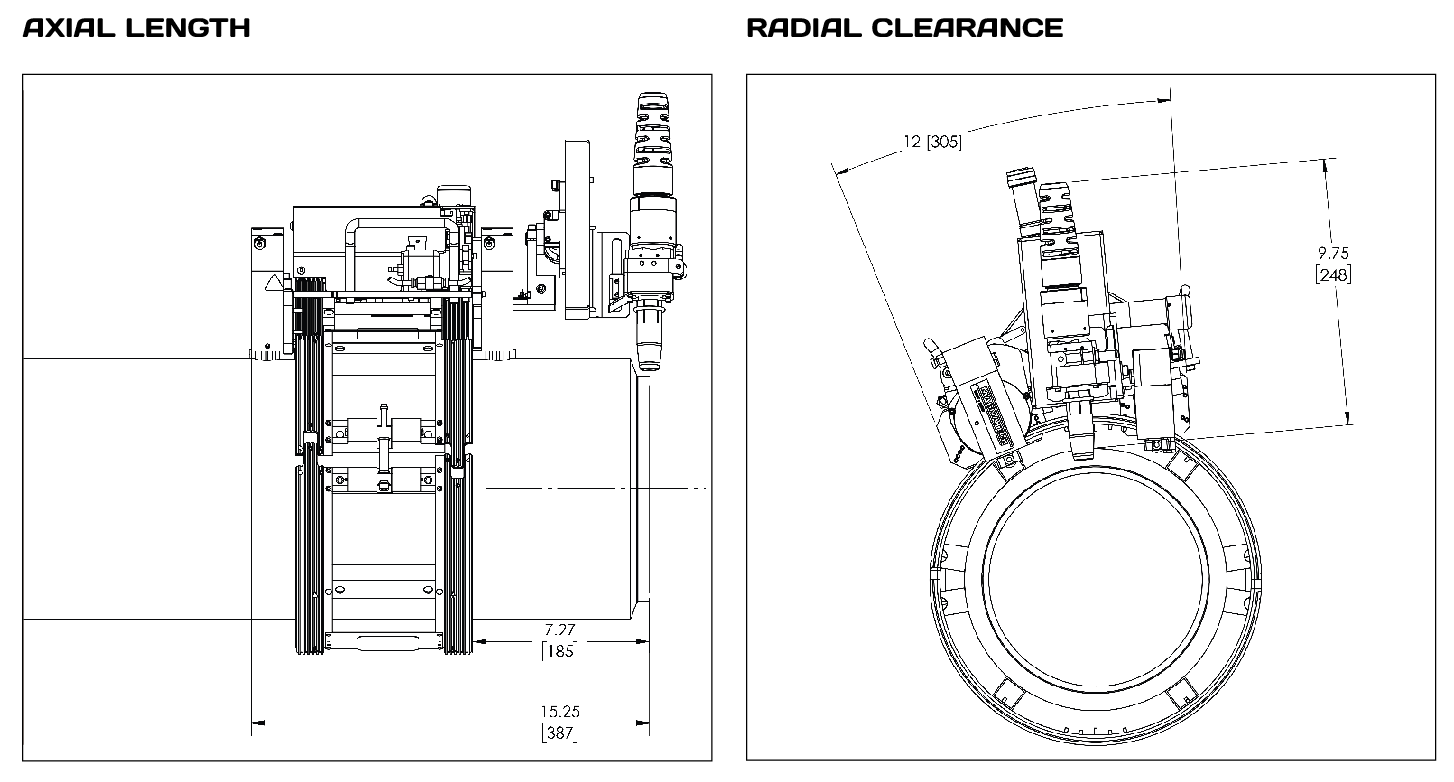

- The Pipeliner Pro welding head Model 616 (Part No: 6160HEB000)

- The digital inverter power source TPS400i (Part No.: TPS400i)

- The welding head controller Model 716 (Part No.: 7160GMB0M0)