Orbital welding is the automatic welding of tubes or pipe in-place with a rotating tungsten electrode. Orbital welding equipment using the Gas Tungsten Arc Welding (GTAW) process can be used for simple fusion welding, and with the addition of filler wire.

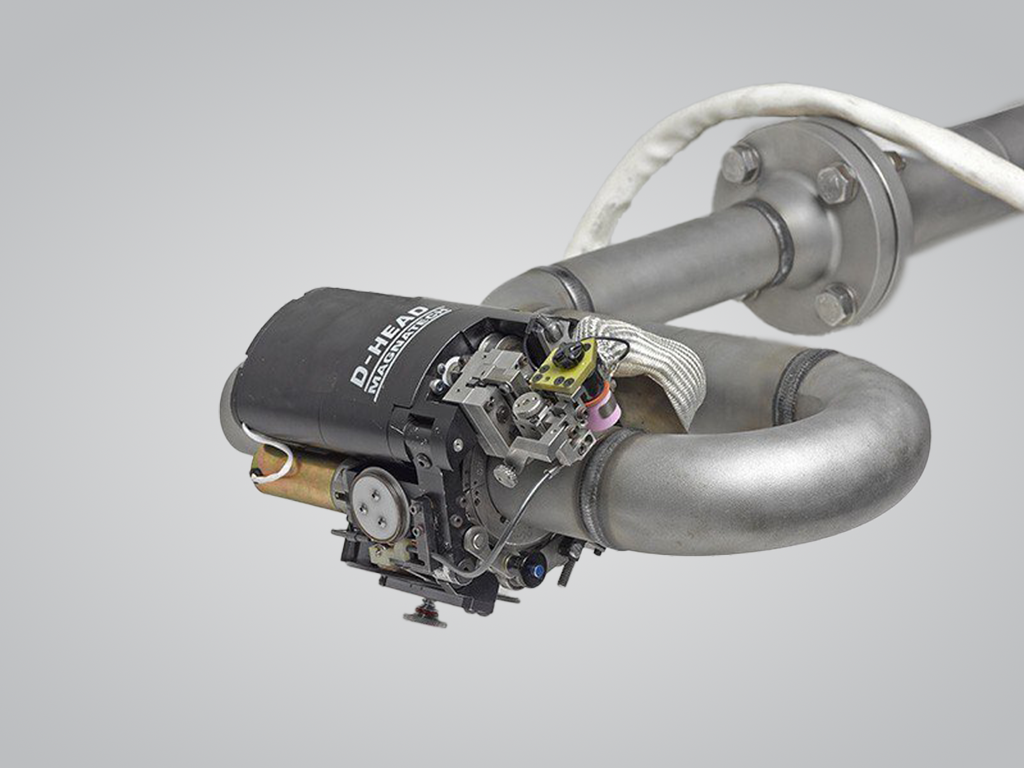

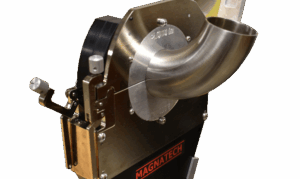

Orbital tube welding was developed in the 1950s, replacing compression fittings and manual welds in the aerospace industry. Technological advancements have made programming and operation simple. Enclosed weld heads can operate on diameters 0.125” (3mm) up to 6 “ (168.3mm), and open weld heads using interchangeable guide rings can mount on a pipe of any diameter.