- Function: multi-pass orbital GTAW pipe-to-pipe, pipe-to-fitting

- Materials: carbon-based and exotic alloys

- Power supply compatibility: Pipemaster 515 and Pipemaster 516

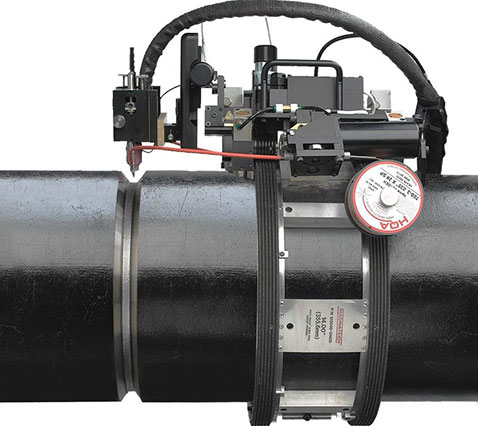

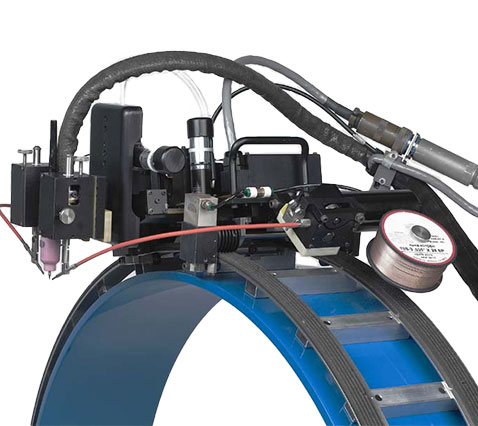

The Magnatech T-head 419 welding head is designed to make pipe-to-pipe and pipe-to-fitting welds. Its full function capabilities allow it to replicate all the motions of a skilled manual welder.

The T-Head 419 welding head is used for larger diameter/ heavy wall applications, requiring GTAW process. Interchangeable guide rings provide mounting on the pipe, allowing the welding head to cover a broad size range.

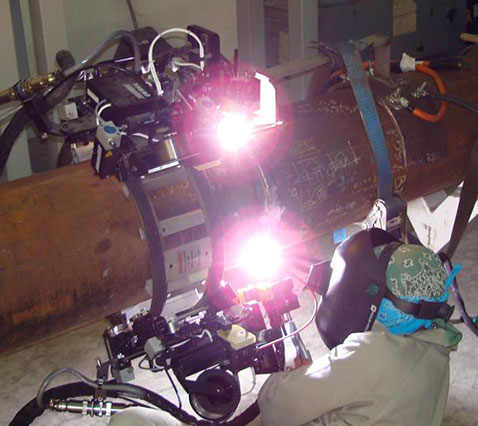

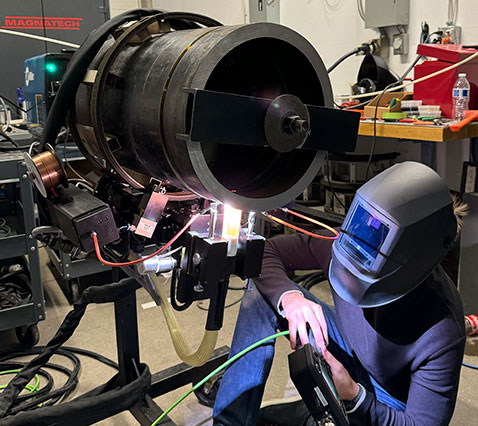

Mounting the head on an oversize guide ring with adaptor feet allows use on materials requiring preheat. In addition to welding pipe, the T Head 419 is also used for ID and OD welding on larger tanks, vessels, and ductwork. This versatility is made possible by a patented flexible track system, enabling stable installation on complex, curved surfaces.

The T-Head 419 welding head improves productivity by increasing duty cycle and reducing repair rates.