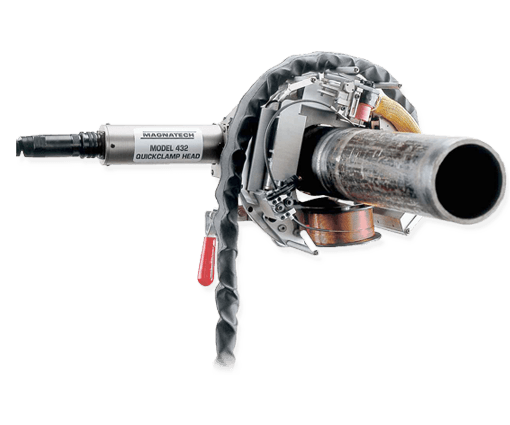

Quickclamp 432 433

Orbital Weld Heads for Multi-Pass GTAW Pipe Welding

The Magnatech Quickclamp weld heads are designed to make pipe-to-pipe and pipe-to-fitting welds. They are “full function” – with the capability of reproducing all the precise motions of a skilled welder. A continuously adjustable clamp eliminates the need to interchange components when changing pipe sizes. Simply slip the head over the pipe and clamp with a toggle lever. The Quickclamp heads improve productivity by increasing duty cycle, reducing repair rates, and producing welds of consistent quality.

Download/View PDF Request Quote

OPTIONS

TILT-AVC standard. Allows the torch to be pivoted for socket/fillet welding applications, maintaining the arc length correction motion along the tungsten electrode axis (tilt-torch bracket also provided standard

Applications

- Fossil Power Plant Construction/Maintenance

- Steam Generation Equipment Fabrication

- Nuclear Power Plant Construction/Maintenance

- Shipyard Construction

- Fabrication Shops

- Chemical/Petrochemical Facility Construction and Maintenance

- Process Piping

Features

- Multipass welding of tubes/pipes in all gravity positions

- Use economical standard 1 kg (2 lb.) wire spools

- Push button clutch for rapid cable unwind

- Heat tolerant steel bearings and chain drive

- Waterproof Carry Case/Tool Kit standard

- Socket Welding Kit and Tilt AVC option for angled torch applications

- Water-Cooled Torch uses standard expendables

Messages Tab

QUICKCLAMP 432, 433

| Specifications | ||

|---|---|---|

| Quickclamp Model 432 | Quickclamp Model 433 | |

| Application | Multi-pass orbital GTAW pipe-to-pipe, pipe-to-fitting | |

| Pipe (tube) OD size range | 25 – 89 mm (1.0” – 3.5”) | 60 – 168 mm (2.375” – 6.625”) |

| Filler wire module | Wire size: 0.8, 0.9, 1.0 mm (.030, .035, .040”) Max. speed capability: 2540 mm/min. (100 IPM) |

|

| Oscillation module | Max. oscillation stroke amplitude: 16 mm (0.625”) Max. oscillation speed: 1520 mm/min. (60 IPM) Oscillation dwell: 0 – 1 second Cross seam adjustment: ± 6.4 mm (± 0.25”) |

|

| Arc gap control module | 13 mm (0.5”) stroke. Additional mechanical adjustment allows welding heavier wall pipe |

|

| Torch propulsion module | 0.1 – 1.8 rpm | 0.05 – 0.9 rpm |

| Water-cooled torch | 200 A continuous | |

Torch adjustment capability |

Torch lead/lag adjustment: ± 15 degrees (manual) Torch tilt adjustment: ± 10 degrees (manual) |

|

| Power supply compatibility | Pipemaster 515, Pipemaster 516 | |

|

||

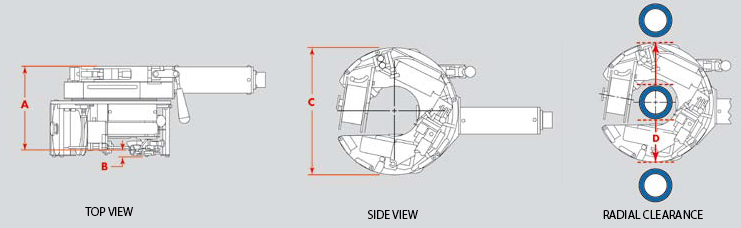

| Dimensions/weights | ||

| Quickclamp Model 432 | Quickclamp Model 433 | |

| Weight | 5.9 kg (13.0 lb.) | 8.1 kg (17.8 lb.) |

| Axial Clearance (Torch Centerline to Rear Extremity) (A) | 158 mm (6.24”) | 158 mm (6.24”) |

| Axial Clearance (Torch Centerline to Front Extremity) (B) | 10 mm (0.41”) | 10 mm (0.41”) |

| Width (C) | 241 mm (9.50”) | 321 mm (12.63”) |

| Radial Clearance Requirement (D) | 241 mm (9.50”) - Pipe OD 321 mm (12.63”) - Pipe OD ÷ 2 = Radial Clearance ÷ 2 = Radial Clearance |

|